Relays

Hi Rocky,

A relay is a simple on/off switch; however, because it's an electro-magnet (rather than a lever, button, etc.):-

. It's switched on and off by something else - my uses are simple so I operate them with the handlebar switches (mainly).

. By different internal connections, a relay can be configured to do different things when it's on and off.

. It allows the electrics designer to let a user operate a heavy current without bringing the heavy current anywhere near the user. The example that you're likely most familiar with is a car electric-starter - you've seen the thick cables between it and the battery, but they don't run to the ignition key switch, and the switch itself doesn't have to be hefty to switch the starter current itself; essentially, the key switch just switches a relay (usually somewhere in the engine compartment), the relay makes the actual connection between battery and starter and away it goes. :thumb

Standard relay:-

The electro-magnet is the oblong symbol between terminals 85 and 86; say, for the sake of argument, this was a starter relay:-

. The ignition key switch would be connected to either 85 or 86 and the other terminal would be 'earthed'.

. The supply from the battery to the starter would be connected to 30 and 87.

. When the ignition switch is turned to 'Start', it operates the relay electro-magnet (very small current, milliAmps usually);

the relay electro-magnet operates the relay switch to connect battery to starter. That's why the thick starter cables don't have to go all the way up the steering column to the ignition switch itself.

. When the engine starts, you release the ignition key, the switch springs back to something like just an 'On' position, the current through the starter relay electro-magnet is cut, it no longer maintains the connection between 30 and 87 so the starter switches off.

Relating the above to, say, the bike's headlamp:-

. The original headlamp (main) was either 45W or 50W.

. This current - ~4A - travels from the battery along the Brown/Blue, jumps the ignition switch contacts, travels along the Brown/White to the toggle switch, jumps the switch contacts, travels along the Blue(?) to the handlebar dipswitch, jumps the switch contacts, travels along the Blue/White to the headlamp bulb.

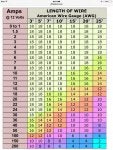

. As I was increasing headlamp main to 100W, I was doubling the current to (a little over) 8A (and might've increased it again to 10A for twin 60/55 headlamps). Problem I had without relays was the extra Amps would be travelling down the same cables and leaping the same switch contacts as the Amps for everything else; increasing

some cable sizes wasn't a problem, but others (e.g to and from handlebar switch clusters) would be, as would the various switches themselves. And the main fuse would have to be even bigger, offering even

less actual protection to most circuits.

. Otoh, if I installed a separate supply direct from the battery to just the headlamp, incorporating relays for main and dip (the relays switched by the handlebar dipswitch), it could be fused to suit just the headlamp consumption, and remove a hefty current from the main loom components. :doublethumb

their "function/position" in the circuitry and suitable relays to buy?

But, if you're only planning to fit a single 60/55 headlamp, note I posted, "it's debateable whether the 5A [i.e. at most, 1.5A more than standard] draw of standard 60W-main-beam warrants the complication of relays ...?"

Nevertheless, I've done it on my T100 and the relevant components are the same on your T140:-

. My T100 was fitted originally with a thicker Brown/Blue than the original on your T140; if you intend to follow my advice and fit a 28/0.30 thinwall cable, it's 25A rating will be more than adequate for all the current, as will a 15A blade main fuse.

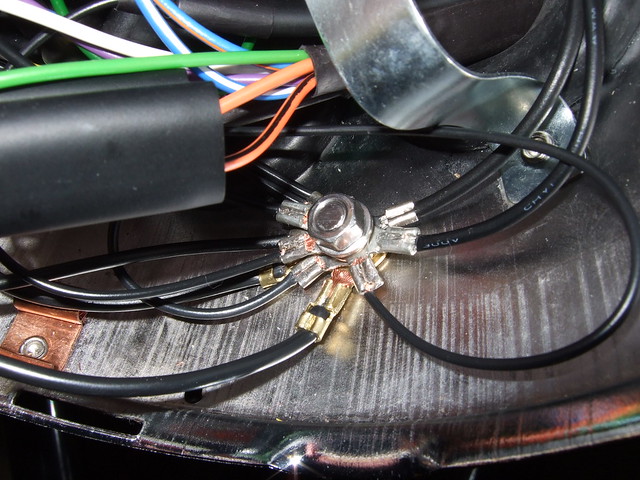

. My T100's ignition switch is a late (but pre-Wassel) proper 'genuine' Lucas with four male tab contacts in two physical pairs. So I have the Brown/Blue to one tab and the headlamp relays' supply from the other physically-connected tab, so the headlamp current itself doesn't pass through the switch itself.

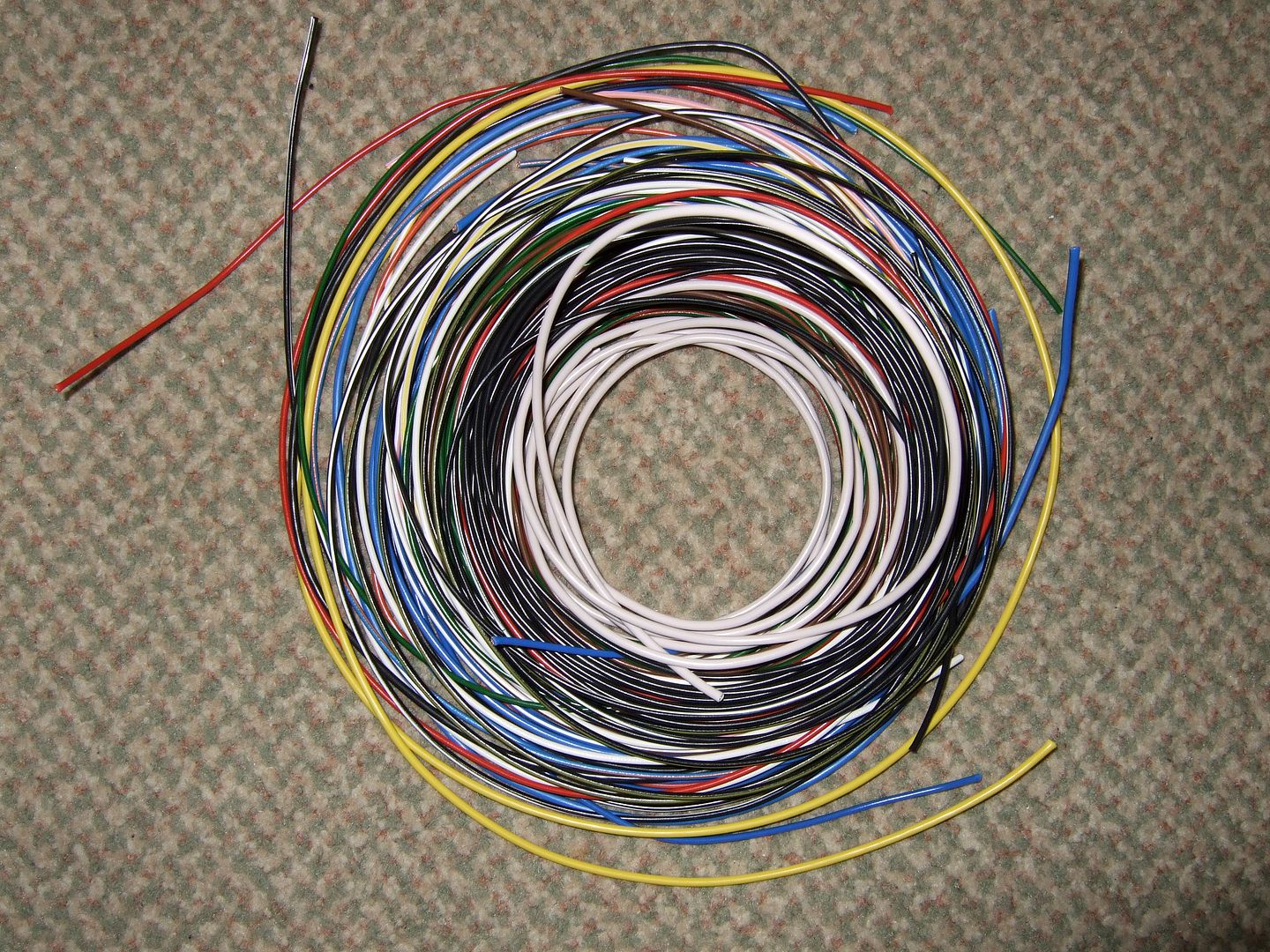

. I've been able to fit the headlamp relays in the standard 'half-egg' shell (with an ammeter as well as the toggle switch

).

.

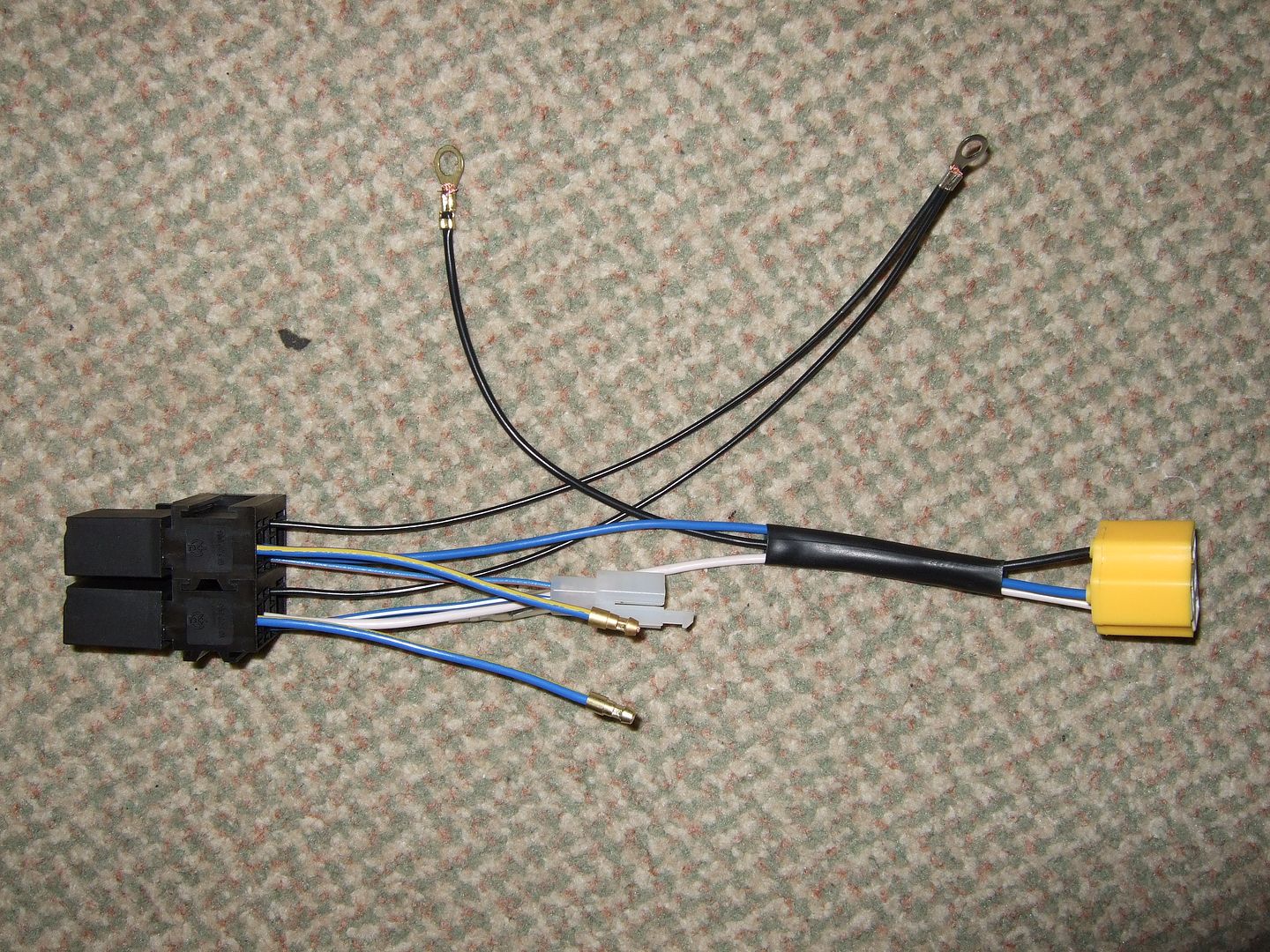

Standard on/off relay with fuse in component supply between terminals 30 and 87.

.

Standard on/off relay without fuse.

. I use one of

these on each relay to keep the individual connections together and in the correct orientation.

. If you're worried about space in the headlamp shell, you can use

micro relays but they don't have the option of an individual fuse and, ime, you definitely need one of

these to keep the individual connections together.

Note all the above are standard relays; as well as being used in other vehicles, you can get 'em from electronics sellers, either bricks-'n'-mortar stores or Ebay, no need to order from GB or the US.

. Assuming standard 'positive earth':-

.. Blue/White or Blue/Red is connected from the handlebar dipswitch to terminal 86 on a relay;

.. Red is connected to terminal 85;

.. battery supply is connected to terminal 30;

.. using BS Au7 colour combos.:-

... Blue/Slate (Grey) or Blue/Black from main-beam relay terminal 87 to headlamp;

... Blue/Pink or Blue/Orange from dip-beam relay terminal 87 to headlamp.

Final two thing to bear in mind:-

. Using the Brown/Blue from battery to ignition switch for the headlamp supply is only suitable for a 60/55 headlamp; if you plan to fit a higher-Wattage one - or keep the dip on when main's on (modern automotive fashion) - you need a completely-separate fused supply all the way from battery to relays.

. Do it as above and, if it all goes horribly pete, just disconnect the headlamp dipswitch Blue/White and/or Blue/Red from the relay/s, connect it/them directly to the headlamp and it'll all work as normal. :thumb

Hth.

Regards,